Technology

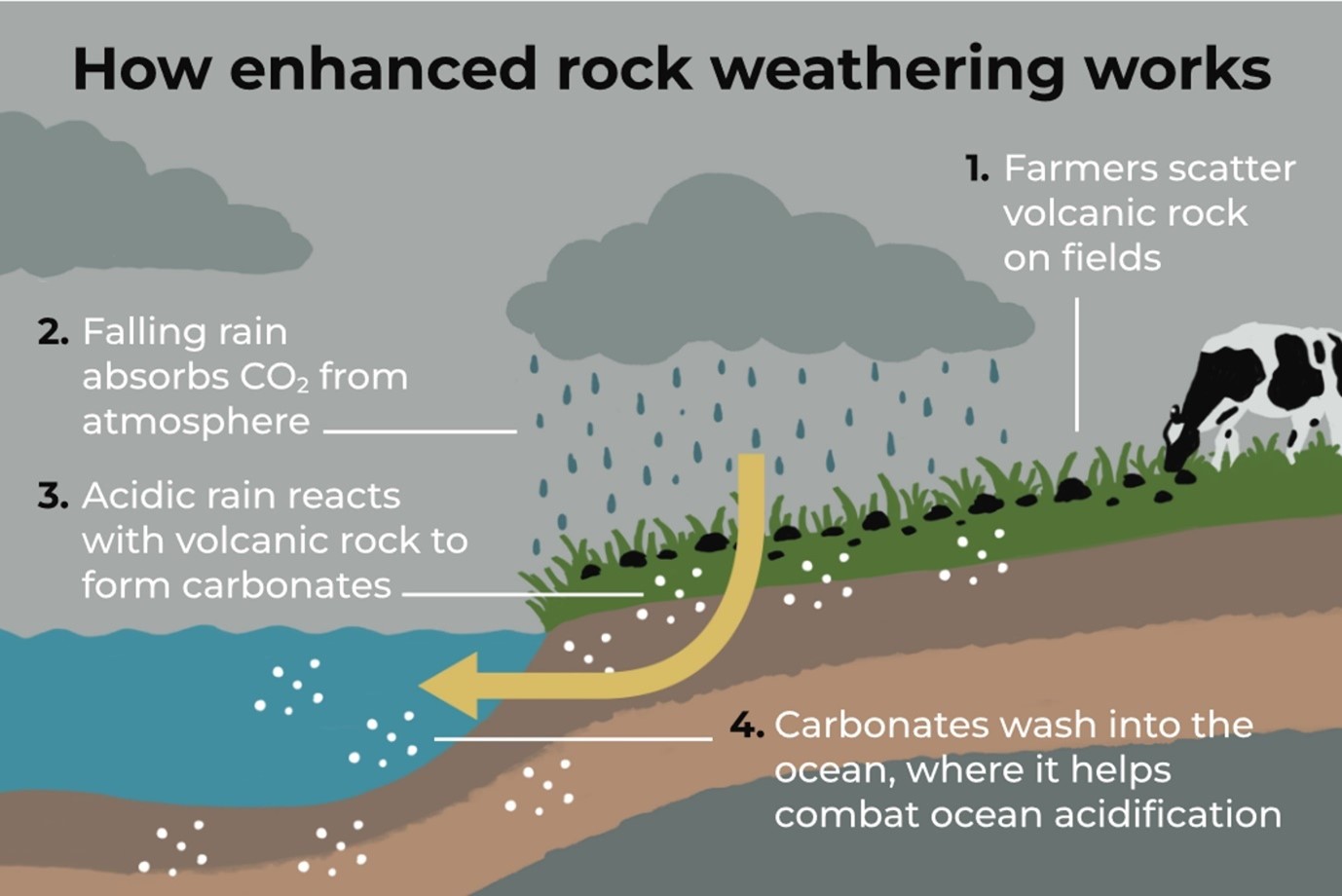

Enhanced Rock Weathering is a carbon dioxide removal technology that accelerates the natural process of rock weathering to capture and sequester atmospheric CO₂. In nature, this process occurs over thousands of years and longer, as rocks slowly react with CO₂ and water, releasing cations and converting CO₂ into bicarbonate and carbonate ions in water. Enhanced rock weathering speeds up this process by selecting reactive rocks—such as ultramafic and mafic rocks like dunite and basalt—grinding them into fine particles, and spreading them over land. By increasing the surface area of the rocks, enhanced weathering promotes their ability to react with CO₂, making the process significantly more effective. Once dissolved, the carbon can remain trapped in water as bicarbonate or carbonate ions or eventually form solid carbonate minerals, which provide long-term sequestration. Some of this dissolved carbon is transported to the ocean through runoff, where it can be sequestered for tens of thousands of years or longer, helping to mitigate climate change (Fig. 1).

Figure 1. Enhanced rock weathering improves soil health, sequesters carbon, and combats ocean acidification. Credit: AGU Advancing Earth and Space Sciences.

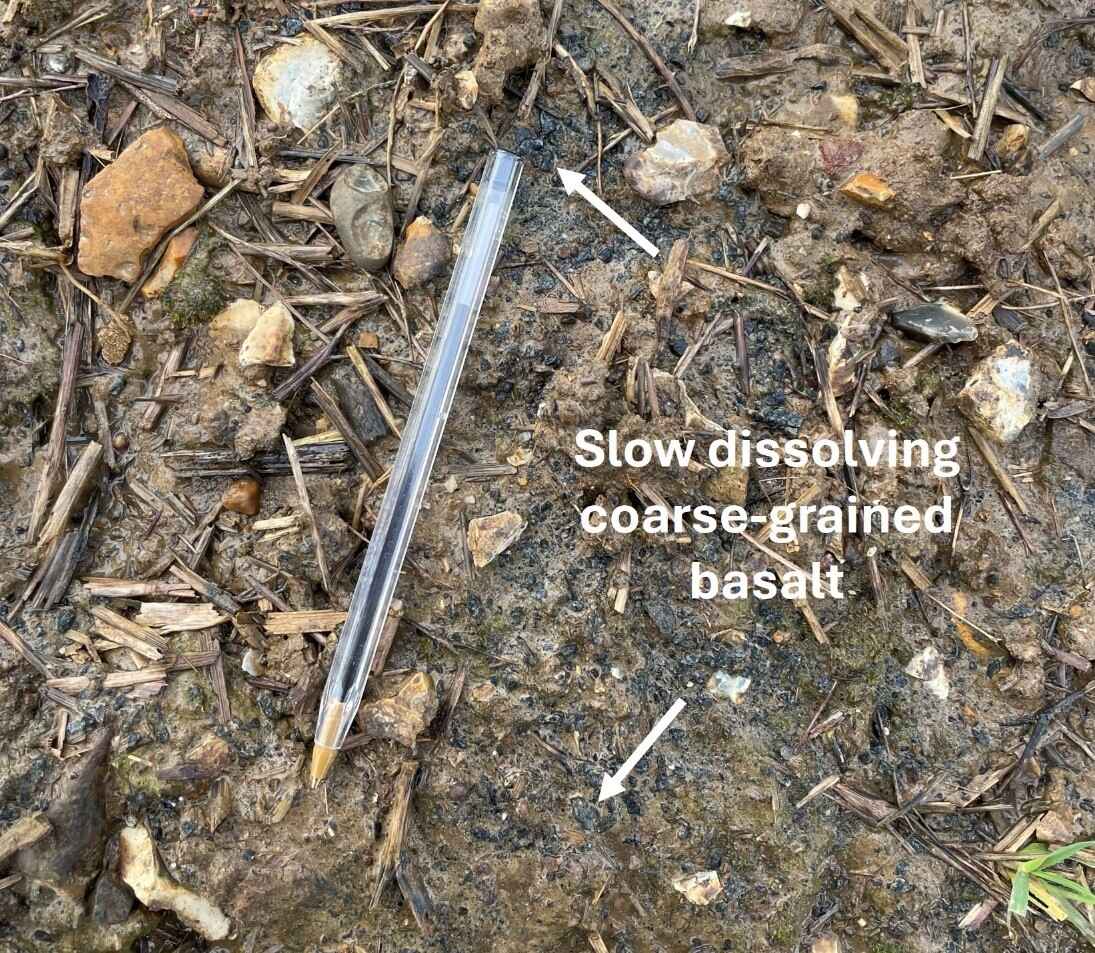

The efficiency of enhanced rock weathering depends on multiple factors, including rock type, particle size, soil conditions, and climate. Smaller rock particles dissolve faster because they have a larger surface area available for chemical reactions (Fig. 2). However, grinding rocks to very fine particles requires energy, creating a trade-off between reaction efficiency and the overall energy cost of the process. Once spread on agricultural or forest soils, these minerals interact with soil microbes, which can further enhance their breakdown and reaction with CO₂. Soil pH plays a key role, as acidic soils can speed up mineral dissolution, making the process more effective. Additionally, temperature influences efficiency of the technology, as lower temperatures allow more CO₂ to dissolve in water, whereas higher temperatures increase the rate at which minerals and react with CO₂ and water. As the rocks dissolve, they release important nutrients into the soil, increasing its alkalinity and potentially benefiting plant growth. Over time, carbonate minerals may precipitate under alkaline conditions, permanently sequestering CO₂.

Figure 2. Enhanced rock weathering trial by spreading basalt on arable land at Rothamsted Research Harpenden, UK. Fine-grained basalt has been dissolved, whereas coarse-grained basalt is still visible on the soil, six months after spreading. Image ©Evangelos Mouchos.

Pilot studies

The C-SINK project explores the potential of enhanced rock weathering, as a sustainable carbon dioxide removal technology, through pilot studies conducted at two active mining sites: the Boliden Kevitsa mine in Finland and the Pasek Minerales David mine in Spain.

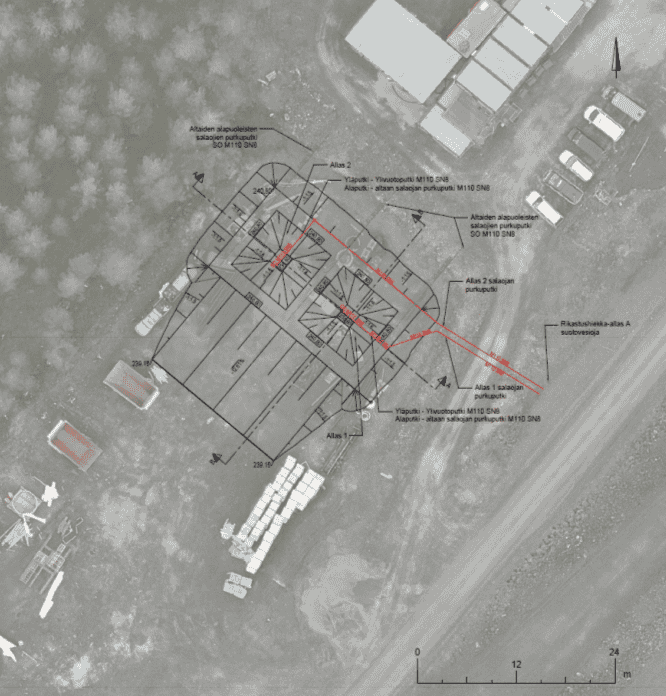

At Kevitsa, an open-pit Ni, Cu, Au, Pt and Pd mine, the pilot focuses on the carbonation potential of ultramafic mining wastes (Fig. 3), and acid mine drainage mitigation under arctic conditions. The pilot is assessing the in-situ CO2 emission versus sequestration potential of tailings material during mining operations, without additional treatment. A control and an experimental cell are constructed at the Kevitsa tailings storage facility (Fig. 4), filled with low-S beach tailings fine-grained (>1 mm) material, composed of Mg- and Ca-bearing silicate minerals.

Figure 3. Ultramafic mining waste rock hand specimen at Boliden Kevitsa mine, Finland. Image ©Steven Pearce.

Figure 4. Experimental cell design at Boliden Kevitsa mine, Finland.

Pilot at David mine focuses on the CO2 removal efficiency of dunite waste produced in the quarry (Fig. 5), compared with artificial soil and biochar synergies for maximising CO2 capture and sequestration, under a mild oceanic climate. Fine-grained (<3 mm particle size) dunite material is spread on a control and a testing plot vegetated with seeds of native herbaceous and shrub species. The other four plots are composed of different combinations of artificial soil with dunite and/or biochar, and are also vegetated (Fig. 6).

Figure 5. Pasek Minerales fine-grained (<3 mm particle size) dunite used at David mine pilot. Image ©Pasek Minerales.

Figure 6. Experimental set up at Pasek Minerales David mine (Plot 1: artificial soil, Plot 2: artificial soil with biochar, Plot 3: artificial soil with dunite, Plot 4: artificial soil with biochar and dunite, Plot 5: dunite, Plot 6: control).